Editorial note: This is the first post from a long article / short book I am working on. Or rather I was working on till I realised my woodworking skills were to poor to talk confidently about them. Now it's time to give it another try. If you thought this blog was not weird enough, here you have a treat: I want to study crafts in phenomenological way and obtain the political consequences of it. In an image, it's like a dream where you are sitting in Alicia's tea party with the rabbit, Bill Gates, Stalin and Tyler Durden. Then Marx comes with something in his hand and hits you with it in the head, while telling you as if you were a retard: "it's the means of production, stupid!". Then you see that in his hand he has the bone of the 2001, space odyssey.

As machines stared to take the place of man in the production of commodities, men felt that their place in the world was disappearing. Somebody invented a machine to create a product. The machine needed several operators, each one with his own particular task and ignorant of the full process. Cogs in the machine, metaphor and normative rule for men in factories. Furthermore, since the task required no skill, the work was poorly paid and the previous knowledge on how to make things, accumulated over centuries, constantly extended, refined and adapted to new tasks, was allowed to die away. We can find a beautiful and emotive recount of this tragic period in the memories of George Sturt, wheelwright.

I take extracts form (Kleinberg-Levin, 2005) since I still need to buy Sturt's book and his introduction is worth quoting at length:

I would like to register, here, the memories of George Sturt, wheelwright, recorded and published in 1923, soon after the end of the First World War, lamenting the devastating sacrifice of the fir-woods required by the war, lamenting, in that loss and its consequences, nothing less than “the death of Old England”. The trees might grow again. “But what would never be recovered”, he says, “because in fact War had found it already all but dead, was the earlier English understanding of timber, the local knowledge of it, the patriarchal traditions of handling it.” Anxious to bear witness to these traditions, to ensure the handing down, if not of the skills he inherited, at least the testimony and celebration of a way of life the passing of which he can only regard with immeasurable sadness, Sturt writes:

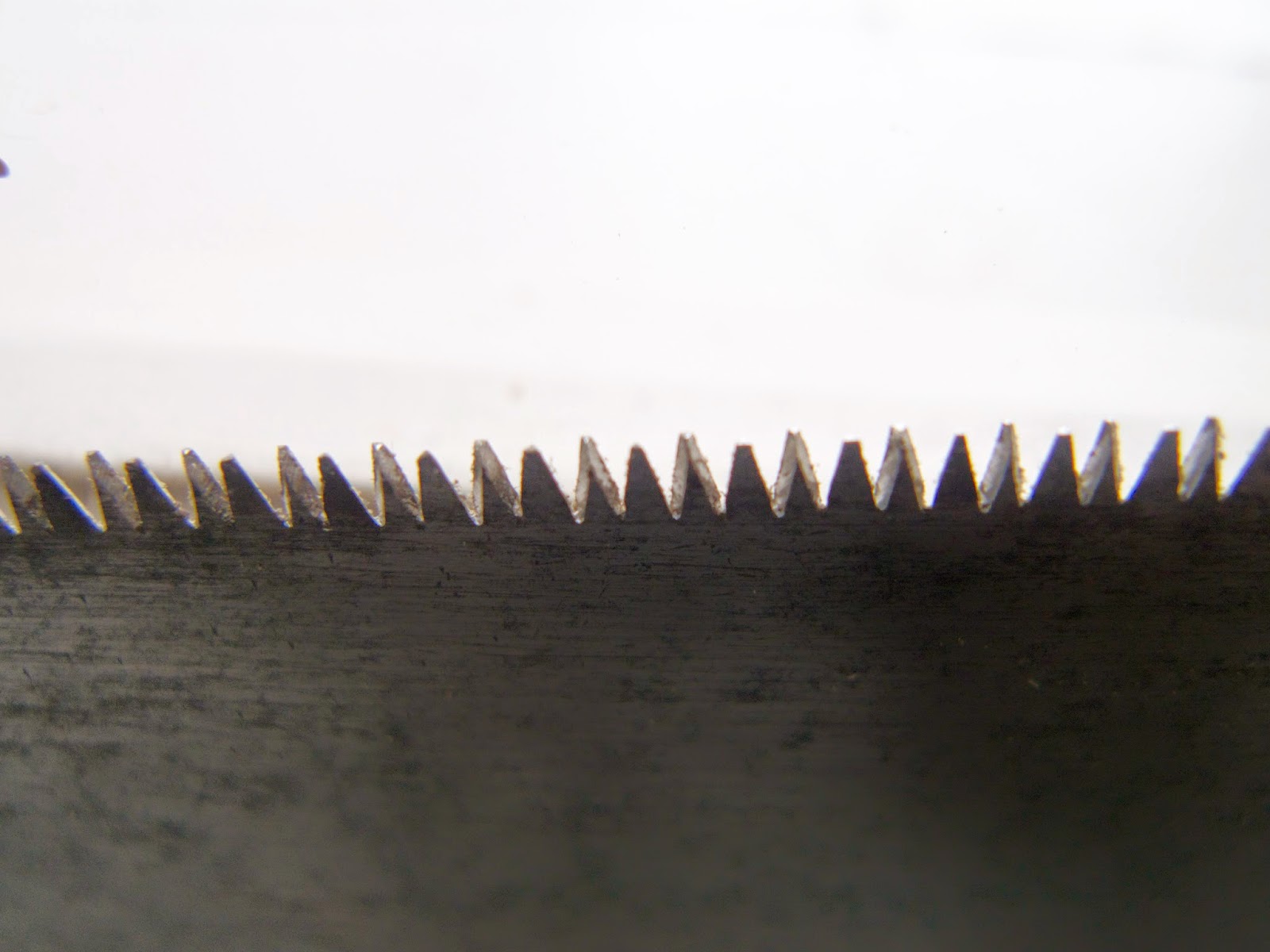

I have known old-fashioned workmen refuse to use likely-looking timber because they held it to be unfit for the job.... Under the plane (it is little used now) or under the axe (it is all but obsolete) timber disclosed qualities hardly to be found otherwise. My own eyes know because my own hands have felt, but I cannot teach an outsider, the difference between ash that is “tough as a whip cord” and ash that is “frow as a carrot” or “doaty” or “biscuity”. (WS 24)

Referring to an old wheelwright he once knew, Sturt says: “He knew, not by theory, but more delicately, in his eyes and fingers...” (WS 54).

“He knew in his eyes and fingers.” Let’s listen once again to what this sentence says. He knew in his eyes and fingers. Knowledge is not something that one possesses, but rather something inhabiting us, in our eyes and fingers, part of our flesh. My fingers know something I cannot talk about. The implicit understanding of what knowledge is that we see here is something completely different to what we (or I should say maybe mainstream cognitive sciences?) understand today. Knowledge not as a formula, not as a computer program, not as something to learn in front of a computer for later vomit it into a multiple choice test as Bologna reforms understands it, but as something that inhabits our body, something that we are not necessarily conscious of.

(We need, then, a theory of knowledge that puts knowledge not in abstract definitions or mathematical formulae, but in a body; that considers knowledge an embodied action: "My own eyes know because my own hands have felt." A theory that understands cognition as something inherently related to, and not separable from, motor action. Several authors have worked along this direction. Francisco Varela and his coworkers in neurobiology and cognitive sciences, and the philosophical work of Evan Thompson and Andy Clark in the last years, rooted on the work of Husserl, Merleau-Ponty and Jonas, form the conceptual framework for this theory.)

The old wheelwrights knew what they knew because of what Sturt describes as a certain “intimacy” with their materials and tools: they “were friends, as only a craftsman can be, with timber and iron. The grain of the wood told secrets to them” (WS 55). Such was the nature of the wheelwright’s marvellous transpersonal wisdom, a wisdom transcending the identity of its subjects, handed down in and by their hands from one generation to the next:

In farm-yard, in tap-room, at market, the details were discussed over and over again; they were gathered together for remembrance in village workshops; carters, smiths, farmers, wheel-makers, in thousands handed on each his own little bit of understanding, passing it to his son or to the wheelwright of the day, linking up the centuries. But for the most part, the details were but dimly understood; the whole body of knowledge was a mystery.... (WS 74)

The old-timers “knew,” he says, “better than any other may do, the answer of the elm when the keen blade goes searching between its molecules”. Then, with modesty and self-effacement, he adds that, “This was, this is, forever out of my reach” (WS 101). Today, he declares, the craftsman has become nothing but “a cog in the industrial machine”, a worker-employee struggling to make ends meet within an economy driven by capital and mar- ket demands. “But”, he states,

... no higher wage, no income, will buy for men that satisfaction which of old – until machinery made drudges of them – streamed into their muscles all day long from close contact with iron, timber, clay, wind and wave, horse-strength. It tingled up in the niceties of touch, sight, scent.... But these intimacies are over. (WS 202)

How to explain this sense of intimacy that the craftsman has with the material world? Why is Sturt so sad about such a loss? Why no higher wage, no income, can fulfil the lack? The answer seems obvious to me: it is an act of love to work with your hands in close contact with iron and timber. But not only that, there is also the social consciousness of doing something greater than yourself and not only for yourself, you are fulfilling a duty.

And this duty, were I to become more ontological, fulfils a need of Being. Following Heidegger, we can listen Holderin’s claim: “But the rock needs engraving/ And the earth needs its furrows;/ If not, an endless desolation; (Es brauchet aber Stiche der Fels/ Und Furchen die Erd,/ Unwirtbar waer es, ohne Weile;)” And endless desolation of a being without scratches, the perfectly dreadful calm of nothingness. “Es brauchet aber Stiche der Fels” But it needs – engravings – the rock.

Varela, in an interview appeared in the documentary “Monte Grande”, explains how the flower dreams of the bee, and the bee dreams of the flower. And how biologically, if you take one out of the environment, both die. What if we take this notion further to include humans in the dreams of stones?

Freud has a most beautiful yet mysterious sentence: “Happiness is the deferred fulfilment of a prehistoric wish. That is why wealth brings so little happiness; money is not an infantile wish.” Mysterious for its ambiguity, whose prehistory is he talking about? The first sentence has an almost ontological weight, in that it may refer to humanity as such: man will be happy when the wishes of his past are finally fulfilled. But then he links it to one particular life: money is not an infantile wish.

The deferred fulfilment of the stone's dreams are its engravings, and of the earth are its furrows. And fulfilling those prehistoric, and also prehuman, dreams is what makes man and the world happy. Look at the plane from yesterday, hanging there next to her japanese sisters, she has found a place and has created a world for herself.

Malarkey! I hear someone yelling at the bottom. A british lad I guess. But I rather have my fellows dreaming of imaginary beings than eating themselves to death in mcdonals or advocating unlimited growth in a finite planet.

References:

David Michael Kleinberg-Levin. The invisible hands of capital and labour: Using merleau-pontys phenomenology to understand the meaning of alienation in marx's theory of manual labour. Philosophy & Social Criticism, 31(1):53–67, 2005.

Further reading:

Varela, Thompson & Rosh,

The Embodied Mind

Andy Clarck,

Out Of Our Heads

Hans Jonas,

The Phenomenon of Life

Thompson,

Mind in Life